hardness test methods ppt|types of hardness testing methods : specialty store Knoop and Vickers are referred to as micro-hardness testing methods on the basis of load and indenter size. Both are well suited for measuring the hardness of small, selected specimen .

Pinguim Academy: Aprenda Laravel. Primeira academia de programação. Não apenas proporcionamos um conhecimento completo sobre o ecossistema Laravel, mas também capacitamos você a se tornar um Product Engineer. Conheça nossos cursos. Assine agora mesmo por apenas! R$ 67/mês. R$ 737/ano. 1 mês grátis 😉. Assine agora. Aprendendo desde o.

{plog:ftitle_list}

WEBPânico 3 (2000) Imagem: Divulgação. Sinopse: Enquanto Sidney e seus amigos visitam o set de Hollywood de Stab 3, o terceiro filme baseado nos assassinatos de Woodsboro, outro assassino de Ghostface parece aterrorizá-los. Onde assistir: Paramount+, Globoplay e .

The document discusses different hardness testing methods including Brinell hardness testing and Rockwell hardness testing. Brinell hardness testing involves pressing .The document provides information about different hardness tests for materials, .Brinell Hardness test is best for measuring hardness of Grey C.I. casting consisting .

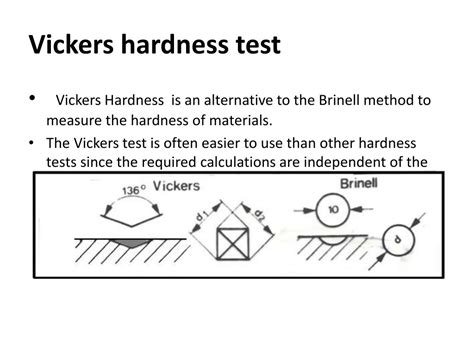

The document discusses various hardness testing methods including indentation hardness tests like Brinell, Vickers and Rockwell as well as microhardness tests. It provides details on the procedure, equipment, and . The document provides information about different hardness tests for materials, including Brinell hardness test, Rockwell hardness test, and Vickers hardness test. It explains how each test is conducted, the equipment used, .Knoop and Vickers are referred to as micro-hardness testing methods on the basis of load and indenter size. Both are well suited for measuring the hardness of small, selected specimen .

Hardness is measurement of a material’s ability to withstand permanent deformation under an applied (known) force. It’s important to have standardized techniques in measuring a materials .Key Words: Hardness Testing, Brinell, Vickers, Rockwell, Mechanical Properties. Type of Module: PowerPoint presentation with lab or in-class demonstration depending on .

Hardness Measurement Methods • Brinell hardness test. • Rockwell hardness test. • Vickers hardness test. • The three methods determine the metal's resistance to the penetration of a non-deformable ball , cone and .This document discusses mechanical properties testing, specifically hardness testing. It provides details on: - Common hardness testing techniques like Brinell and definitions of hardness versus microhardness. - Hardness is a . Brinell Hardness test is best for measuring hardness of Grey C.I. casting consisting of soft flake graphite, iron & hard iron carbide. The main drawback of the Brinell test is the need to optically measure the indent size.

vickers hardness test ppt

Hardness Testing of Materials. Elizabeth Merten University of Washington, Seattle Department of Materials Science & Engineering. Key Concepts. Hardness is measurement of a material’s ability to withstand . 4. Determination of Hardness • The hardness of water can be estimated by methods such as gravimetric analysis, EDTA titration, atomic absorption, etc., • In the above methods, EDTA titration is the most . The document discusses different hardness testing methods. It describes Brinell hardness testing which uses a 10mm steel ball indenter under a load of 3000kg to test hardness. Vickers hardness testing uses a diamond . 2. What is NDT? • Nondestructive testing or non-destructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or .

3. ROCKWELL HARDNESS TEST The differential depth hardness measurement was conceived in 1908 by a Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method subtracted out the errors associated with the mechanical imperfections of the system, such as backlash and surface imperfections. IES-2002 Assertion (A): The hardness test is a slow, expensive method of assessing the mechanical properties of materials. Reason (R): The hardness is a function of yield stress and the work hardening rate of material. (a) Both A and R are individually true and R is the correct explanation of A (b) Both A and R are individually true but R is .

Hardness levels are classified as soft, moderately hard, hard and very hard. Both advantages like reduced heart disease and disadvantages like economic losses due to scaling are covered. Methods for removing temporary and permanent hardness are also outlined. Read less

1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:This article discusses the 9 sand test types methods and equipment used in the foundry to test moulding sand with the proper formula, diagrams, summary, PPT and animation. The list of moulding sand testing methods is as follows: Permeability test. Hardness test. Moisture content test. Clay content test. Grain fineness number (GFN). Hardness Measurement Methods • Brinell hardness test. • Rockwell hardness test. • Vickers hardness test. • The three methods determine the metal's resistance to the penetration of a non-deformable ball , cone and pyramid. • The tests determine the depth which such a ball or cone will sink into the metal, under a given load, within a .

Hardness - Download as a PDF or view online for free. 13. • 1822: Friedrich Mohs (Ger) - A ten-point scratch hardness Mohs scale. • 1900: J. A. Brinell (Swe) - A ball indentation / dent dia size Brinell Hardness. • 1920: S. R. Rockwell (US) – Minor, major load / dent depth Rockwell Hardness. • 1925: R. Smith and G. Sandland (Eng) – Diamond pyramid indenter / .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds. • Download as PPT, PDF . Rockwell hardness testing involves indenting a material with either a diamond or steel ball indenter under a minor preload and then a major load. The difference in indentation depth is used to determine the Rockwell hardness number on various scales. There are 30 Rockwell scales that use different indenters and loads.

types of hardness testing methods

3.1.4 Rockwell superficial hardness test—same as the Rock-well hardness test except that smaller preliminary and total test forces are used. 3.1.5 verification—checking or testing to assure conform-ance with the specification. 4. Significance and Use 4.1 The Rockwell hardness test is an empirical indentation hardness test. Rockwell hardness test is the most commonly used method for indentation hardness measurements. The value of Rockwell hardness is accompanied by the scale used. Depending on the material being tested, an . Micro hardness testing involves forcing a diamond indenter with a specific geometry into the surface of a test piece under a small load, then using a microscope to measure the resulting indentation to determine the hardness; . The hardness testing methods used frequently across the technology field are separated into methods with static and dynamic force applications. When testing the hardness of metals, static forces are .

Key Words: Hardness Testing, Brinell, Vickers, Rockwell, Mechanical Properties . Show the PowerPoint presentation and discuss each slide. a. Slide 1-2: Introduction to Hardness (key concepts) b. Slide 3: Diagrams of typical machines and indenters c. Slide 4: Experimental Set-up d. Slide 5: Example of Indentation and Schematic of various indenters 11. Vicker Hardness Test:- The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in .The most basic and commonly used definition is the resistance of a material to permanent, plastic deformation. While other forms of hardness testing, such as rebound, electromagnetic, and ultrasonic, are used in a variety of applications and measure material hardness through other techniques, indentation hardness testing provides reliable, straightforward, and a commonly .

used to perform the Brinell hardness test. 3.1.7 Brinell hardness testing machine—a Brinell hardness machine used for general testing purposes. 3.1.8 Brinell hardness standardizing machine—a Brinell hardness machine used for the standardization of Brinell hardness test blocks. The standardizing machine differs from a regular Brinell . The document discusses hardness testing methods. It describes how hardness is defined differently depending on one's field, such as resistance to indentation for metallurgists. . Brinell Hardness Test • The Brinell hardness testing consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball(10mm) subjected . Hardness test - Download as a PDF or view online for free. Submit Search. Hardness test . Rockwell hardness test principle The Rockwell method measures the permanent depth of indentation produced by a force/load on an indenter. First, a preliminary test force (commonly referred to as preload or minor load 10 kgf) is applied to a sample using . Measuring hardness using differential depths helps to eliminate errors due to surface imperfections. In addition, the hardness value can be read with no additional optical equipment, making it one of the most common hardness testing methods. The Rockwell test is described in ASTM E18 – 20 (Standard Test Methods for Rockwell Hardness of .

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative . 4. Dissolution test: Drug should be released from tablet in a controlled and reproducible way. Weight variation, thickness & diameter: The appearance of tablet should be elegant & its weight, size & appearance should be consistent. Hardness & friability: The tablet should show sufficient mechanical strength to withstand fracture & erosion during manufacture .

Hardness testing is perhaps the simplest and the least expensive method of mechanically characterizing a material. This article provides an overview of the principles of hardness testing. It compares Brinell with Meyer hardness testing and hardness testing of fully cold worked metals with fully annealed metals.

polarimeter experiment youtube

polarimeter explained

Resultado da 19 sec Oficial-Xvideos - 1080p. Contratei essa empregada, eu não aguentei de tanto tesão, ela é muito safada, quis me dar 5 min. 5 min Electra Oficial - 671.1k Views - 1080p. Professora de Academia dá aula pelada, ela é muito safada 5 min. 5 min Electra Oficial - 695.8k Views -

hardness test methods ppt|types of hardness testing methods